Gel, copper, and graphite each boost cooling foam performance by improving heat transfer and moisture management. Gels absorb and dissipate heat quickly, copper’s high thermal conductivity accelerates heat flow from your skin, and graphite reflects infrared radiation to keep temperatures lower. While they enhance comfort, limitations like wear and cost vary. Understanding how these materials work helps you choose the best option—stay engaged to uncover more insights.

Key Takeaways

- Gel additives quickly absorb and dissipate heat, providing immediate cooling effects on the skin.

- Copper’s high thermal conductivity enhances heat transfer, accelerating cooling and reducing hot spots.

- Graphite reflects infrared radiation, maintaining lower skin temperatures through its layered structure.

- Combining gel, copper, and graphite improves foam performance, durability, and heat dissipation efficiency.

- Material choices impact cost, longevity, and environmental sustainability of cooling foam products.

What Makes a Cooling Foam Effective and What Ingredients Matter?

To make a cooling foam truly effective, the key lies in its ingredients. Synthetic polymers are essential because they create a gel-like texture that retains moisture and enhances heat absorption. These polymers form a thin, flexible layer on your skin, helping to dissipate heat efficiently. Natural extracts, on the other hand, add soothing properties and improve skin comfort. Ingredients like aloe vera or menthol can provide an instant cooling sensation and reduce irritation. The combination of synthetic polymers and natural extracts ensures the foam delivers quick, lasting relief while being gentle on your skin. Additionally, integrating innovative cloud technologies can optimize the formulation process for better consistency and performance. Understanding the chemical composition of cooling foams helps consumers select products tailored to their needs. When choosing a cooling foam, look for products that balance these ingredients for peak performance and comfort. This synergy makes all the difference in achieving effective, long-lasting cooling. Moreover, heat dissipation is crucial for maintaining a cool feeling over extended periods, making the right formulation even more important.

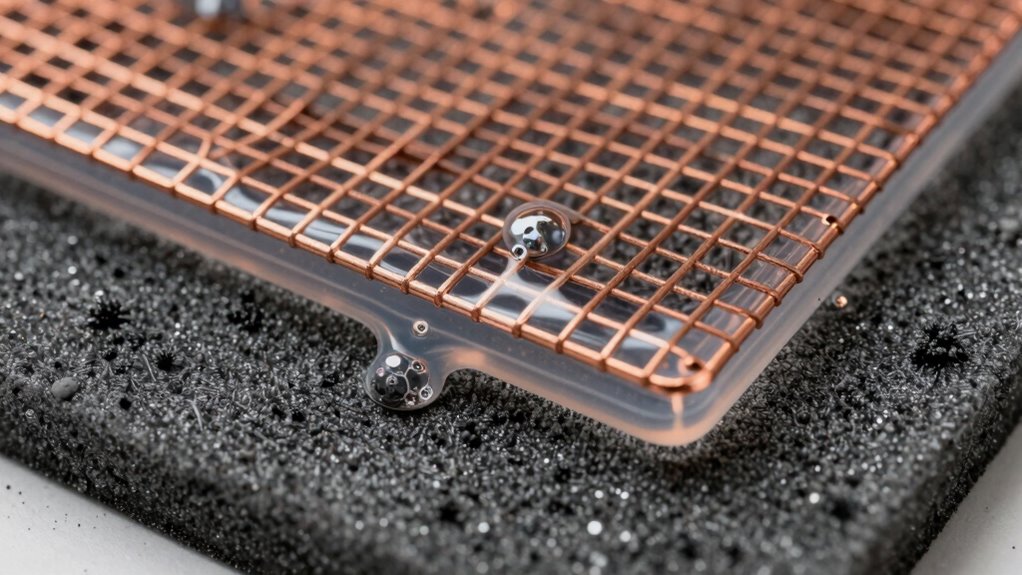

How Do Gel, Copper, and Graphite Improve Cooling Performance?

Gel, copper, and graphite each play a significant role in boosting the cooling performance of foam products. Their material innovation improves heat transfer and moisture management, making the foam more effective at cooling. Gel-based additives absorb and dissipate heat quickly, enhancing comfort while reducing energy consumption. Copper’s high thermal conductivity accelerates heat transfer away from your skin, providing faster cooling effects. Graphite’s layered structure reflects infrared radiation, helping to maintain lower temperatures. These materials also impact environmental considerations; many are chosen for their sustainability or potential for eco-friendly manufacturing. Additionally, understanding the material properties of these substances allows manufacturers to optimize foam formulations for both performance and environmental impact. By integrating gel, copper, and graphite, manufacturers can create cooling foams that perform better and have a reduced environmental impact, addressing both comfort and sustainability concerns in modern product design. Furthermore, ongoing research into sustainable materials aims to improve the eco-friendliness of cooling foams even further. Incorporating advanced composites can also enhance the durability and eco-friendliness of these materials, ensuring long-term benefits.

What Are the Main Benefits of Gel-Based Cooling Agents?

One of the main benefits of gel-based cooling agents is their exceptional ability to absorb and dissipate heat quickly, providing immediate relief when temperatures rise. This rapid heat transfer enhances comfort without long wait times. Additionally, gel cooling agents are known for their safety, often made from non-toxic materials that minimize health risks. Their environmental impact is generally low, especially when biodegradable gels are used, making them eco-friendly options. Gel cooling agents also maintain their effectiveness over multiple uses, ensuring consistent performance. Their flexibility allows them to conform to various surfaces, optimizing contact and cooling efficiency. Moreover, heat transfer efficiency is a critical factor that contributes to their quick cooling capabilities. To maximize their benefits, some products incorporate natural ingredients that can further improve safety and biodegradability. Furthermore, advancements in material technology have led to the development of more durable and efficient gel formulations. Overall, these qualities make gel-based cooling agents a practical, safe, and environmentally conscious choice for cooling needs.

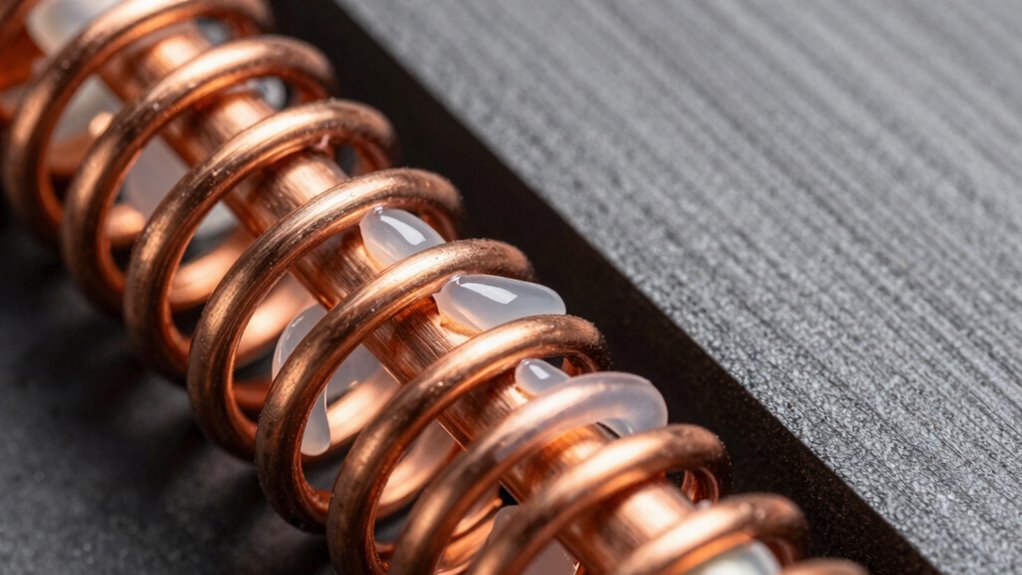

How Well Does Copper Help Dissipate Heat in Cooling Foams?

Ever wondered how effectively copper can dissipate heat in cooling foams? Copper’s high thermal conductivity makes it a strong candidate for heat transfer. When integrated, it accelerates heat dissipation through conduction, reducing hot spots. Material compatibility is crucial to ensure copper functions optimally within foam matrices. Additionally, the manufacturing process of copper-infused foams can influence their overall performance and durability. Proper quality control during production can help mitigate issues related to performance inconsistencies. Furthermore, understanding thermal management principles is essential for optimizing copper-infused foam designs. However, chemical reactions with other foam components can affect its longevity and performance. Its environmental impact depends on extraction and disposal practices, which could pose sustainability concerns. The table below summarizes copper’s role:

| Benefit | Challenge | Environmental Impact |

|---|---|---|

| High thermal transfer | Possible chemical reactions | Mining impacts, waste issues |

| Fast heat dissipation | Corrosion over time | Recycling concerns |

| Enhances foam performance | Compatibility limitations | Eco-friendly alternatives |

Copper helps dissipate heat efficiently but requires careful consideration of chemical reactions and environmental effects. Additionally, ongoing research into sustainable materials aims to find eco-friendlier alternatives to copper in cooling applications.

What Are the Limitations or Drawbacks of Using These Materials?

You might find that some cooling foams don’t last as long as you’d hope, especially with regular use. Cost can also be a concern, making it harder to access these materials for everyone. Plus, durability issues mean you may need to replace or upgrade more often than expected. Additionally, piercing care and hygiene are essential to prevent irritation or infection when using these materials. Proper handling and material storage are crucial to prevent contamination and maintain their effectiveness. Improper handling can sometimes lead to material degradation, reducing effectiveness over time. Furthermore, the regulations and standards surrounding these materials can vary, affecting their safety and performance. Awareness of material safety protocols can help ensure optimal use and longevity of cooling foams.

Material Durability Concerns

Despite their innovative cooling properties, foam materials often face durability issues that can limit their long-term effectiveness. Over time, material degradation can occur, reducing thermal performance. The ingredient longevity of foams varies, influenced by environmental exposure and usage conditions. You may notice the foam becoming brittle or losing its shape, compromising cooling efficiency. Factors such as moisture, temperature fluctuations, and mechanical stress accelerate deterioration. To maintain performance, it’s essential to consider the foam’s resilience and resistance to wear. Regular inspection and proper handling extend the lifespan, but inherent material limitations remain a challenge for long-term applications. Material resilience plays a key role in determining how well these foams withstand environmental stresses. Anticipate these issues to optimize your cooling foam’s performance and lifespan. Proper maintenance practices can significantly impact durability and ensure sustained cooling benefits. Additionally, understanding the material composition helps in selecting the most durable options for specific environments.

Cost and Accessibility

While foam cooling materials offer effective temperature regulation, their cost can be be a significant barrier for many users. The market price varies depending on ingredient sourcing and manufacturing quality, making some options less accessible. High-quality gels, copper, or graphite-infused foams tend to be more expensive due to scarce ingredients and complex sourcing processes. Limited availability can delay procurement, especially for bulk or custom orders. Here’s a quick overview:

| Material | Market Price | Ingredient Sourcing |

|---|---|---|

| Gel | Moderate to High | Specialized chemicals, sourcing varies |

| Copper | High | Copper supply chain, extraction costs |

| Graphite | Moderate | Natural or synthetic sources |

These factors mean affordability and access remain challenges for widespread use. Additionally, supply chain issues can further impact availability and cost fluctuations, emphasizing the importance of understanding market dynamics in material selection. Recognizing how cost factors influence material choice can help users make more informed decisions, especially as material prices continue to fluctuate globally. Moreover, technological advancements may eventually reduce manufacturing costs, making these materials more accessible in the future.

Which Cooling Foam Ingredient Offers the Best Balance of Cost and Cooling Power?

Choosing the right cooling foam ingredient often comes down to finding the best balance between cost and cooling effectiveness. Copper stands out because of its high thermal conductivity, providing strong cooling power without excessive expense. It also offers good material longevity, ensuring durability over time. Graphite is another option, offering excellent thermal conductivity at a lower cost, but it may wear faster. Gel-based ingredients tend to be more affordable and easier to incorporate but may lack in thermal transfer efficiency. Consider these factors:

- Thermal conductivity for rapid heat dissipation

- Material longevity to reduce replacement costs

- Manufacturing costs and scalability

- Compatibility with existing foam structures

- Long-term cooling performance stability

Frequently Asked Questions

How Long Do Cooling Effects Typically Last in These Foams?

Cooling effects in these foams typically last between 2 to 4 hours, depending on factors like thermal longevity and material durability. You’ll notice the cooling diminishes gradually as heat transfers from your body to the foam. To maintain ideal comfort, consider how often you need to flip or reposition the foam, as its thermal longevity influences how long the cooling benefits persist. Proper care helps extend the material’s durability and cooling performance.

Are There Any Safety Concerns With Prolonged Contact With Gel, Copper, or Graphite?

Imagine holding a cool pebble, but prolonged contact with gel, copper, or graphite in cooling foam might cause skin irritation or allergic reactions. While generally safe, extended exposure could lead to discomfort or sensitivities, especially if you have sensitive skin. Always monitor for redness or irritation, and if symptoms appear, remove the foam and consult a healthcare professional. Safety depends on individual skin responses and proper usage.

Can These Cooling Foams Be Recycled or Reused?

You can often recycle or reuse these cooling foams, but recycling challenges exist due to their complex materials and embedded substances. Some foams may be repurposed for insulation or cushioning, boosting their reuse potential. However, separating components like gel, copper, or graphite can be difficult, limiting recycling options. Always check local recycling guidelines and manufacturer instructions to guarantee proper disposal or reuse methods for these cooling foams.

How Do Environmental Factors Influence the Performance of These Materials?

Did you know that environmental factors can decrease cooling foam performance by up to 30%? You should be aware that environmental stability plays a vital role in how well these materials maintain their thermal properties. Exposure to moisture, temperature fluctuations, or UV light accelerates material degradation, reducing effectiveness over time. To maximize longevity, store and use cooling foams in controlled environments, shielding them from extreme weather and harmful elements.

Are There Specific Applications Where One Material Outperforms the Others?

You’ll find that copper excels in specialized industrial uses due to its excellent thermal conductivity, making it ideal for heat exchangers and electronics cooling. Gel is preferred in consumer products like cooling pads or pillows because of its comfort and flexibility. Graphite shines in high-temperature environments, such as aerospace or advanced manufacturing. Your choice depends on whether you prioritize performance in industrial applications or consumer preferences.

Conclusion

Choosing the right cooling foam is like finding the perfect breeze on a scorching day—each ingredient offers its own invigorating touch. Gel, copper, and graphite work together like a skilled orchestra, turning your comfort into a symphony of chill. While each has its quirks, finding the right balance means you can enjoy a cool, calming oasis wherever you go. Embrace these ingredients, and let your comfort soar above the heat.