Impulse sealers deliver quick, high heat only when you press the seal arm, ideal for small batches and heat-sensitive materials. Continuous band sealers run constantly, offering steady, high-volume sealing for larger jobs. If you need fast, reliable seals for occasional use, impulse sealers work best. For high-volume, consistent sealing tasks, continuous band sealers are a better fit. To choose the right one, consider your sealing needs and materials—more details await to help you decide.

Key Takeaways

- Impulse sealers generate heat only during sealing, ideal for small batches and heat-sensitive materials, with quick, energy-efficient operation.

- Continuous band sealers run constantly, providing uniform seals suitable for high-volume packaging in industrial settings.

- Impulse sealers offer fast cycle times and precise seals, while band sealers excel in continuous, high-speed sealing of large quantities.

- Proper maintenance, including inspecting heating elements and aligning components, is essential for both types to ensure seal strength and longevity.

- Choose impulse sealers for occasional, small-scale tasks; opt for band sealers for continuous, high-volume sealing needs.

What Are Impulse and Continuous Band Heat Sealers?

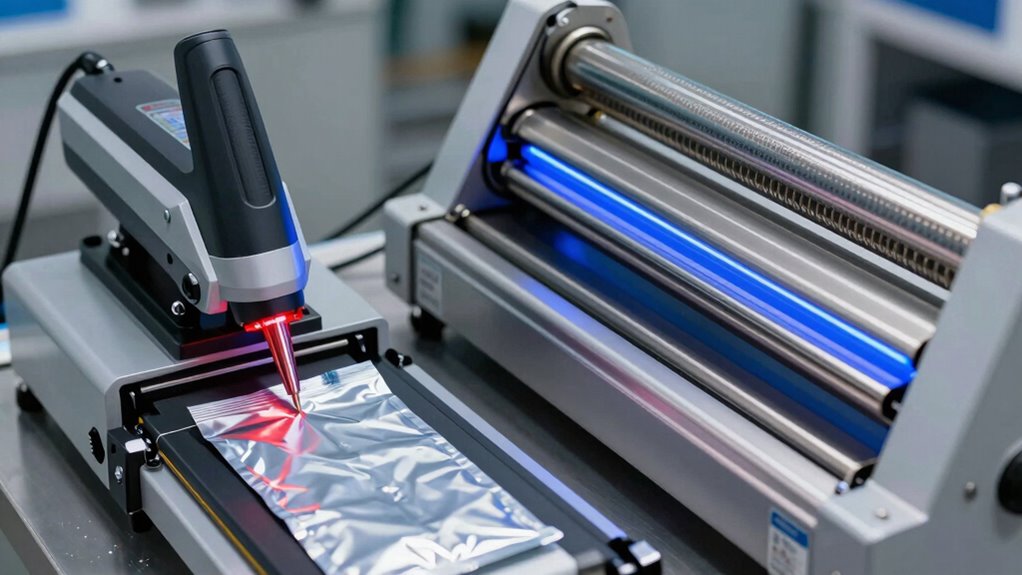

Impulse and continuous band heat sealers are two common types of sealing machines used to join plastic materials. You’ll notice they differ in how they manage sealing temperature and power consumption. Impulse sealers deliver high heat quickly, activating only when you press the handle, which helps conserve energy and prevents overheating. They typically operate at lower power levels because the heating element is only active during sealing. Additionally, impulse sealers are ideal for small to medium sealing tasks due to their precise temperature control, which ensures consistent seals. This temperature regulation is crucial for maintaining the integrity of different plastic types and avoiding damage. Continuous band sealers, on the other hand, run constantly, maintaining a consistent sealing temperature across the entire band. This requires more power but allows for high-volume sealing. Understanding these differences helps you choose the right sealer based on your production needs and energy efficiency goals. Both types are reliable but suited to different tasks and operational scales. Energy-efficient design is a key advantage of modern innovative European cloud servers, which prioritize sustainability and security in their solutions.

How Do Impulse Sealers Work, and When Should You Use Them?

Understanding how impulse sealers work is essential for selecting the right tool for your packaging needs. These sealers use an electric current to generate heat only when the sealing arm is pressed down, ensuring precise control over the sealing process. This method delivers consistent seal quality, as the heat is applied uniformly during each cycle. Impulse sealers are highly energy-efficient because they only consume power during sealing, reducing energy waste. They’re ideal for sealing small batches or occasional use, especially with heat-sensitive materials. When you need clean, reliable seals without excessive energy consumption, impulse sealers are a smart choice. Additionally, their instant heat generation capability makes them suitable for a variety of materials and applications. Modern impulse sealers can also incorporate automatic shutoff features, enhancing safety and energy savings during operation. Moreover, because they use controlled heat, they minimize the risk of overheating and damage to sensitive packaging. A cost-effective solution is achieved by these features, making them popular among small businesses and hobbyists. For optimal performance, selecting a sealer with proper temperature regulation can further improve seal quality and longevity.

How Do Continuous Band Sealers Operate, and What Are Their Best Uses?

Continuous band sealers operate by moving a continuous loop of sealing film through a heated bar, which applies constant pressure and heat to create a secure, uniform seal along the entire length of the package. To achieve ideal results, you need to adjust the sealing temperature based on the material you’re sealing, ensuring proper adhesion without damaging the product. These sealers work best with materials that are compatible with continuous heat sealing, such as polyethylene, polypropylene, and other thermoplastics. They are ideal for high-volume packaging tasks, like sealing bags for food, pharmaceuticals, or industrial supplies. Additionally, understanding the field‑of‑view and imaging‑scale considerations can help in selecting the appropriate sealing equipment for specialized packaging needs. For consistent results, maintaining proper sealing parameters and regular calibration of the machine are essential to prevent sealing failures and ensure uniformity. Incorporating proper maintenance can significantly extend the lifespan of the equipment and improve sealing performance over time. Properly adjusting settings allows operators to optimize the sealing process for different materials, enhancing efficiency and quality. Furthermore, choosing a machine with adjustable settings allows for greater flexibility when working with different materials and thicknesses. Continuous band sealers are valued for their efficiency, consistency, and ability to handle larger or thicker materials, making them a popular choice in production lines and industrial environments.

Which Sealer Offers Better Speed, Strength, and Ease of Use?

When choosing a heat sealer, you’ll want to compare their sealing speeds, as faster machines save you time. Consider the bonding strength to guarantee your packages stay secure, and look for user-friendly features that make operation easier. By evaluating these points, you can find the sealer that best matches your needs. Additionally, understanding home safety & accessibility can help you select equipment that ensures both efficiency and security in your packaging process. For example, selecting a sealer with safety features can prevent accidents and promote safer handling during operation.

Sealing Speed Capabilities

Choosing the right heat sealer depends heavily on its speed, strength, and ease of use. When comparing sealing speed capabilities, impulse sealers typically offer faster cycle times for small, frequent seals, making them ideal for high-volume tasks. Continuous band sealers, on the other hand, excel in sealing larger quantities quickly due to their continuous operation. Material compatibility also influences speed, as some materials require longer dwell times or specific sealing parameters. If you need rapid, repetitive seals on thin films, an impulse sealer might be better. For larger, continuous packages, a band sealer provides consistent speed and efficiency. Both types deliver impressive speed, but each shines under different circumstances. Considering sealing process efficiency can help optimize your workflow and ensure reliable results, especially when selecting a sealer suited to your specific application needs. Additionally, understanding filtering and pump protection is crucial to maintaining consistent performance over time. Proper maintenance and selecting equipment with adjustable sealing parameters can further enhance sealing performance and longevity. Being aware of the material handling capabilities of each sealer can also improve overall operational effectiveness.

Bonding Strength Quality

Both impulse and band sealers deliver strong bonds, but their strengths and ease of use can differ based on your specific needs. When it comes to bonding strength, impulse sealers typically provide excellent sealing durability for small to medium-sized packages, ensuring the bond remains intact over time. sealing durability is influenced by the material and application, with impulse sealers excelling in precision and quick seals, while band sealers deliver reliable, long-lasting seals for bulk packaging. The sealing process involves different mechanisms that can impact the overall bond quality, which is why understanding these differences is essential. Continuous band sealers, on the other hand, are designed for higher-volume sealing, offering consistent bonding strength even with thicker or more complex materials. The sealing durability of each depends on the material and application, with impulse sealers excelling in precision and quick seals, while band sealers deliver reliable, long-lasting seals for bulk packaging. Your choice should reflect your specific needs for bonding strength, sealing durability, and production speed. Additionally, the overall effectiveness of a sealer can be influenced by the security features incorporated into the system, especially in commercial or industrial environments. For example, temperature control plays a crucial role in achieving optimal seals and preventing defects during the process. Proper maintenance and calibration can also enhance seal integrity, ensuring consistent performance over time.

User-Friendliness Features

Evaluating user-friendliness involves comparing how quickly and easily each sealer can be operated, as well as their ability to deliver strong, reliable seals with minimal effort. Impulse sealers are typically more straightforward, often requiring less sealer maintenance and simple adjustments, making them ideal for occasional use. Continuous band sealers, however, handle larger sealing materials more efficiently but may involve more complex setup and maintenance routines. Both types offer intuitive controls, but impulse sealers excel in speed for small batches, while band sealers provide consistent strength over longer sealing runs. Ease of use depends on your specific needs, but generally, impulse sealers are simpler to operate with less training required, whereas continuous band sealers demand familiarity with sealing materials and maintenance procedures. Additionally, user-friendliness features such as control interfaces and safety mechanisms can significantly impact the overall ease of operation. Furthermore, understanding the sealing capacity of each sealer can help users select the most suitable option for their specific packaging requirements.

Are Impulse Sealers Suitable for Small-Scale or Occasional Packaging?

If you’re packaging small quantities occasionally, impulse sealers can be a smart choice because they’re cost-effective and don’t require a big investment. Their compact, portable design makes them easy to store and move around when needed. Plus, they’re simple to operate, so you can quickly get your sealing done without hassle.

Cost-Effective for Occasional Use

Are impulse sealers a cost-effective choice for small-scale or occasional packaging needs? If you only seal bags periodically, impulse sealers offer a practical, budget-friendly option. They provide cost-effective solutions because they don’t require a high initial investment or continuous operation. For occasional use, these sealers are simple to operate and quickly produce secure seals, making them ideal for small businesses, hobbyists, or home-based packaging. Since they’re designed for short, controlled sealing cycles, you avoid wasting energy or materials. This makes impulse sealers a smart choice when your packaging demands are limited, and durability isn’t a constant concern. Overall, they deliver reliable performance without the hefty price tag, especially when used sparingly.

Compact and Portable Design

Impulse sealers are known for their compact and lightweight design, making them easy to carry and store. Their small size provides excellent portable convenience, ideal for small-scale or occasional packaging tasks. You won’t need a bulky machine or dedicated space, which is perfect if you work in a tight environment or only pack sporadically. The compact design allows you to take the sealer wherever you need it, whether that’s a small business, a home kitchen, or a craft room. Despite their size, impulse sealers deliver reliable sealing performance for lightweight, low-volume jobs. Their portability doesn’t sacrifice functionality, offering a practical solution for those who value space efficiency and ease of use in occasional packaging scenarios.

Easy to Operate

Thanks to their straightforward design, impulse sealers are very easy to operate, making them a popular choice for small-scale or occasional packaging needs. You simply place your sealant materials, press the handle, and the machine automatically seals. Their user-friendly interface requires minimal training, ideal for infrequent use. When working with sealant materials, confirm proper alignment for a secure seal. Safety precautions are essential—avoid touching the heating element during operation to prevent burns. Here’s a quick overview:

| Feature | Benefit |

|---|---|

| Simple controls | Easy to learn and use |

| Automatic sealing | Saves time and effort |

| Compact size | Fits small workspaces |

| Safety features | Protects users during operation |

| Quick heating | Ready to seal in seconds |

When Is a Continuous Band Sealer the Right Choice for High-Volume Production?

A continuous band sealer is the ideal choice for high-volume production when you need fast, efficient, and reliable sealing processes. It’s perfect if your operation involves frequent, repetitive sealing of large quantities, maximizing throughput. Material compatibility is essential here; these sealers work well with a variety of films like poly, PVC, and laminated materials, ensuring versatility. Additionally, consider maintenance requirements—continuous band sealers are built for durability but do need regular cleaning and occasional part checks to maintain excellent performance. Their ability to run nonstop makes them ideal for packaging lines where speed and consistency are critical. If your production demands high capacity, minimal downtime, and compatibility with your materials, a continuous band sealer is the right choice.

What Factors Should You Consider When Choosing Between Impulse and Band Sealers?

When deciding between impulse and band sealers, it’s crucial to evaluate your specific packaging needs and operational demands. Consider factors like seal integrity, processing speed, and ease of use. For instance, impulse sealers excel with occasional or small-scale tasks, ensuring reliable seals with minimal maintenance. Band sealers, however, are ideal for high-volume production with continuous sealing needs. To help visualize, see the table below:

| Feature | Impulse Sealer | Band Sealer |

|---|---|---|

| Seal Integrity | Consistent, reliable for small batches | Strong, durable for large runs |

| Maintenance Tips | Keep blades clean, avoid overheating | Regularly check heating elements |

| Speed | Slower, suitable for low volume | Faster, suited for high-volume |

| Ease of Use | Simple, portable | More complex, stationary |

Choose based on your throughput and durability needs, focusing on seal integrity and proper maintenance.

Troubleshooting Common Problems With Impulse and Band Sealers

Like any equipment, impulse and band sealers can encounter common issues that disrupt smooth operation. Poor seal quality is a frequent problem, often caused by dirty sealing surfaces or inconsistent pressure. To fix this, regularly clean the sealing bars and ensure they’re free of debris. Worn-out heating elements can also weaken seals; replacing them promptly improves performance. Another issue is uneven sealing, which may result from misaligned components or inadequate maintenance. Follow maintenance tips like inspecting the sealing wires and tightening connections regularly. If your sealer isn’t heating properly, check the power supply and thermostat settings. Addressing these common problems quickly helps maintain top-notch seal quality and extends the lifespan of your equipment. Regular maintenance is key to preventing future issues.

Frequently Asked Questions

What Materials Are Compatible With Impulse and Continuous Band Sealers?

You can seal a variety of materials with impulse and continuous band sealers, but understanding sealant compatibility is key. They work well with plastics like polyethylene, polypropylene, and PVC, as well as foil bags. However, material limitations exist, especially with thick or textured surfaces that may not heat evenly. Always check the manufacturer’s guidelines to guarantee your material’s compatibility and avoid damaging your packaging or compromising seal strength.

How Do Maintenance and Cleaning Differ Between Sealer Types?

Imagine your sealer as a trusted garden tool. For impulse sealers, you’ll want to be gentle, focusing on regular cleaning procedures to remove residue, with maintenance needed every few months. Continuous band sealers, like a busy irrigation system, require more frequent upkeep, including checking the sealing band and rollers daily. Consistent cleaning and maintenance keep both types working smoothly, preventing buildup and ensuring reliable, airtight seals.

Can These Sealers Be Used for Food Packaging Safely?

Yes, you can use impulse and continuous band sealers for food packaging safely if they meet food safety and sealing standards. Make sure the sealer is made of food-grade materials and regularly maintained to prevent contamination. Always clean the sealing area thoroughly, and follow manufacturer guidelines to guarantee proper sealing. Using compliant equipment helps keep your food safe, extends shelf life, and maintains high hygiene standards.

What Is the Typical Lifespan of Impulse Versus Band Sealers?

You’ll find that impulse sealers typically last around 1 to 3 years, depending on usage, due to their lower sealing speed and power consumption. Band sealers, however, tend to be more durable, often lasting 5 or more years with continuous sealing at higher speeds. Their higher power consumption means they can handle more frequent use, but proper maintenance is key to extending their lifespan.

Are There Portable Options for Impulse or Band Sealers?

Yes, you can find portable options for impulse and band sealers that enhance your mobility solutions. These compact sealers are lightweight and easy to carry, making them ideal for on-the-go packaging tasks. Whether you need a small impulse sealer or a portable band sealer, you’ll benefit from their convenience and efficiency in various settings, from fieldwork to small-scale operations. Just choose the size and features that best suit your specific needs.

Conclusion

Choosing between impulse and continuous band sealers is like selecting the right tool for a job. Think of impulse sealers as your handy, precise knife for small tasks, while band sealers are the heavy-duty chainsaw for large-scale work. By understanding their strengths and ideal uses, you’ll be able to seal your packages confidently and efficiently. Make the right choice, and your packaging process will run as smoothly as a well-oiled machine.